The 80-series Fisher & Paykel stator

put out some nice power. I wanted to see if I could improve

this. I took a 100-series (1mm diameter, 18g magnet wire) and

stripped it bare.

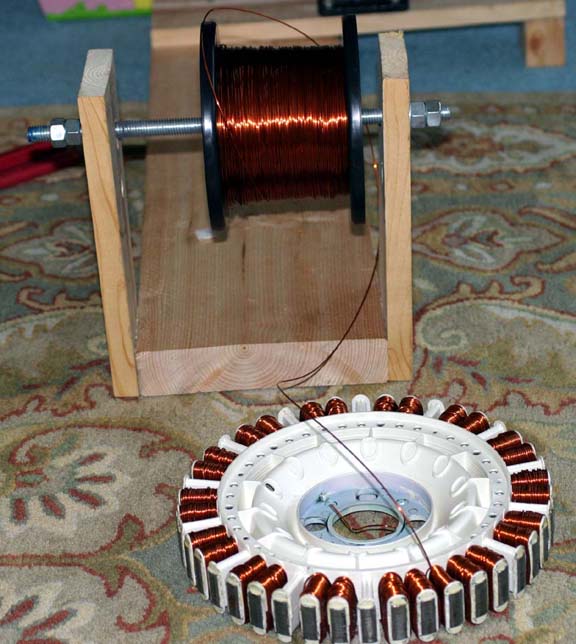

I would have liked it if I could have used my winding rig to rapidly wind each bobbin. This did not happen. The original stator had 44 windings for each of the 52 poles. I wound this by hand using a spool holder, my hands and feet to wind about 70 coils per pole. This is about 1.5x the turns. I did this while watching the news, cartoons and movies. My hands were sore.

You can see on the comparison of the old and new stator how there is more wire for each coil. I also filed the iron down at the edges, making a curve to reduce cogging. There was a big difference.

So now that I did this I had to test the finished product. I ran the original, unmodified stator with the standard ceramic rotor. Next, I tested the modified stator with the ceramic rotor. I measured open voltage and wattage under a 25ohm load which is slightly more than the generator impedance. Maximum power can be extracted from the generator when the two are matched. At 500 RPM I got 327W from the original stator and 410W from the modified stator. Then, I took my modified neodymium rotor and tested it with the modified stator. At 500 RPM I got 1225W. I have graphed the results for all three.

I would have liked it if I could have used my winding rig to rapidly wind each bobbin. This did not happen. The original stator had 44 windings for each of the 52 poles. I wound this by hand using a spool holder, my hands and feet to wind about 70 coils per pole. This is about 1.5x the turns. I did this while watching the news, cartoons and movies. My hands were sore.

You can see on the comparison of the old and new stator how there is more wire for each coil. I also filed the iron down at the edges, making a curve to reduce cogging. There was a big difference.

So now that I did this I had to test the finished product. I ran the original, unmodified stator with the standard ceramic rotor. Next, I tested the modified stator with the ceramic rotor. I measured open voltage and wattage under a 25ohm load which is slightly more than the generator impedance. Maximum power can be extracted from the generator when the two are matched. At 500 RPM I got 327W from the original stator and 410W from the modified stator. Then, I took my modified neodymium rotor and tested it with the modified stator. At 500 RPM I got 1225W. I have graphed the results for all three.