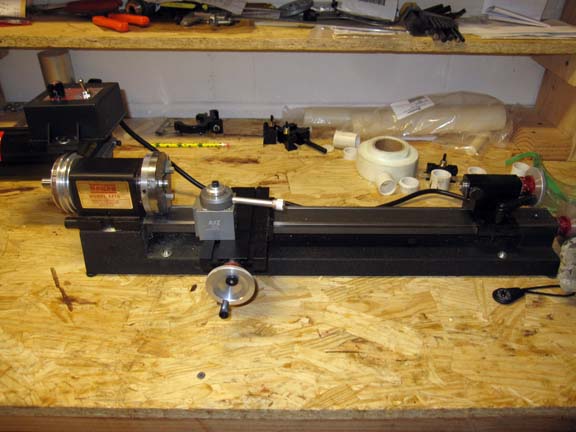

Using a Lathe for Fitting Steel Hub to Rotor

I have found a micro lathe essential for this project. Many times you will need to precisely drill holes and line up rotating objects. I have used the lathe to fabricate bushings that have allowed me to center objects. My microlathe is from Sherline.

I used the lathe because I needed a way to transfer the wind

energy to the magnetic rotor. I thought about having the blades

on one side of the shaft and the rotor on the other. I was

uncertain how well the plastic female receptacle would be over time

from being subjected to the strong torque forces. I decided to

have the blades attach to the rotor itself. The blades would turn

the rotor and the shaft would only serve to keep the rotor

centered. This also allows me to add a disc braking mechanism on

the other side as the electrical brake I contemplated will not be

sufficient to stop the windmill in strong winds.

I acquired the blades and steel hub from TLGWindpower.com. The hub came with a 17mm dead center hole. The screw end of the shaft is 12mm. I dedided to learn how to use a metal lathe and got one from Sherline.com The lathe is precise to 0.01mm. I machined a bushing that just fits over the 12mm screw and just fits into the 17mm hole on the shaft.

With the means to perfectly center the

steel hub on the rotor I precisely drilled holes into the rotor.

Each end of the hub would receive three holes to secure to the rotor

for a total of 9 holes.

I modified the washers so they would

conform to the shape of the rotor on the outside and inside.

Here you can see the complete rotor-hub

assembly. I've sprayed the steel hub and F&P rotor with

rustoleum primer and then enamel. I've coated the grade 8 steel

fully threaded bolts with marine triple-guard grease to protect the

metal from moisture which would cause rusting.

I ran a quick test by overdriving my 1.5hp

motor. Everything ran perfectly: I got 1300watts at 700rpm and

the rotor moved smoothly. When I turn the assembly by hand I

notice the slightest cogging, and that is only because I am looking for

it.